Chimneys for New Build Homes

Installing a chimney in a new build

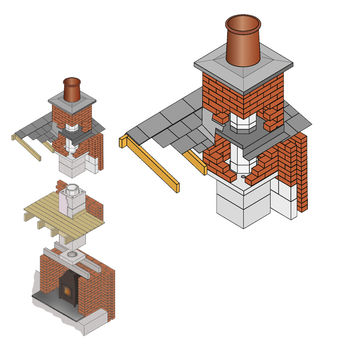

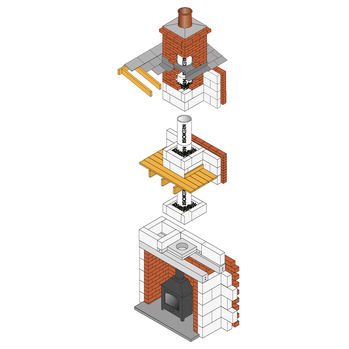

Woodburners require a well insulated chimney to maintain the flue gas temperature and prevent tar condensation in the flueway, which is why concrete or clay liners are not suitable for use with stoves. There are three main choices for forming a chimney - Pumice Liners in a block or brick stack, a Double Module pumice system that forms the complete chimney or a Twin Wall Insulated stainless steel flue.

Pumice liners come in a range of diameters, are 600mm long and rebate into each other as they go up. They are surrounded in the stack by leca granules. If the stack has 100mm blockwork and 75mm of leca insulation then the distance to combustibles from the outside face of the stack is zero. This allows timberwork, insulation and the airtight membrane to be brought right up to the chimney, ensuring that there will be no break in the insulation layer and so avoiding a cold bridge.

The Schiedel Double Module system has hexagonal inner liners and an outer casing, making it very quick and simple to build. On a straight DM stack that employs a top ring terminal, the distance to combustibles is again zero, making floor and roof penetrations simple and safe. An offset stack, or one finishing into a clay pot or other termination, has a zero distance to combustibles for non structural timber and requires a 38mm distance to structural timbers. Again this permits an uninterrupted insulation layer. An airtight gasket can be employed around the stack to maintain the integrity of the airtight membrane.

You can browse the Pumice chimney systems that we offer.

Maintaining air tightness and continuous insulation with a Twin Wall Insulated system

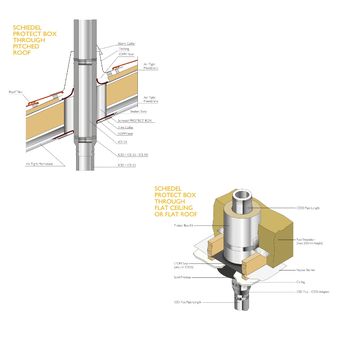

When fitting a stove in a Passiv or highly insulated new build, being able to avoid any break in the insulation or any loss of airtightness is very important. With most twin wall systems an airgap of at least 50mm is required around the pipework which can create a cold bridge. With the Schiedel ICID twin wall system you have the option to employ a Protect Box which ensures that the insulation remains continuous and utilising an EPDM gasket means that there will be no issues around airtightness. To facilitate this, the flue changes at ceiling level to lengths that have 50mm insulation instead of the standard 25mm and the Protect box is positioned around the flue as it passes through the roof space. The protect box can be cut to fit with the roof angle. The normal insulation can be brought right up to the Protect box to create a continuous insulated layer.

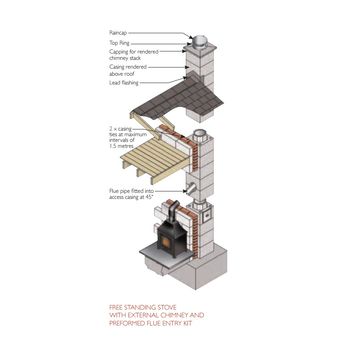

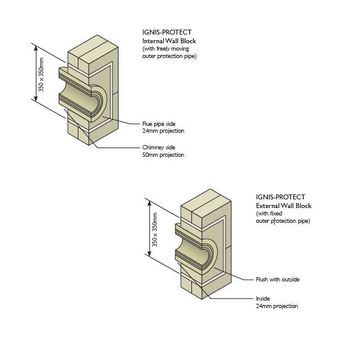

Routing a flue through an external wall

Often flues are routed from the stove, out through the wall and then up the outside, and again special components have been developed by Schiedel to enable the flue to pass through the wall without a break in the insulation or the airtight membrane. This is called the Ignis Protect system and is designed to connect from the stove into an external pumice chimney stack using single skin flue or to facilitate a twin wall insulated flue passing through the wall. Depending on the chimney design, this can be done either horizontally or at a 45* angle. The Ignis Protect system not only ensures continuous insulation and airtightness, it also enables a flue to pass safely through a wall constructed from combustible materials and can be used on internal and external walls.